How to choose plastic lining pump and all plastic pump

-Compared with steel, the physical properties of non-metal are usually much worse, even worse than aluminum and yellow steel, but by increasing the cross-sectional modulus (that is, increasing the wall thickness) and adding ribs and bones. Non-metal can withstand a certain degree of working pressure. With the rapid development of the plastic industry, the variety of plastic pumps is increasing, which is more and more replacing other kinds of non-metallic pumps. The varieties of commonly used plastic pumps are as follows.

-Polyperfluoroethylene propylene is a modified variety of polytetrafluoroethylene, which is prepared by suspension copolymerization of tetrafluoroethylene and hexafluoropropylene at 55-60 ℃, commonly known as F46. F46 has excellent mechanical properties, excellent stability, weather resistance, electrical insulation and flame retardancy, low surface tension and good adhesion to metal in melting state. This material can be used for a long time at-85-205 ℃. The service temperature of the pump made of this material can reach 150 ℃ (200 ℃).

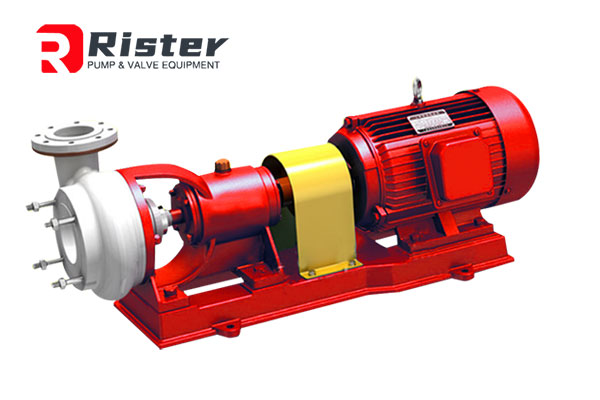

-FSB fluoroplastic centrifugal pump-is a kind of centrifugal chemical pump which was developed earlier and used more commonly. Its pump head is all molded with fluoroplastic, and the main materials are polymer material, F26 material, F46 material and fluoroplastic alloy material. Due to different materials, the price also has a large error. Manufacturers are easy to be confused when choosing, because the materials are selected correctly according to the type, corrosiveness, temperature and concentration of the medium. This kind of pump is generally used to transport chemical fluids in industries and mines where the diameter of the pipeline is relatively small and the flow head is low. Because the pump head is all made of fluoroplastic, so the mechanical strength is relatively weak and easy to crack and aging, so the inlet and outlet pipes of the pump must be disassembled during maintenance. Otherwise, it is easy to damage the pump body due to external force and pipe gravity during maintenance and installation.

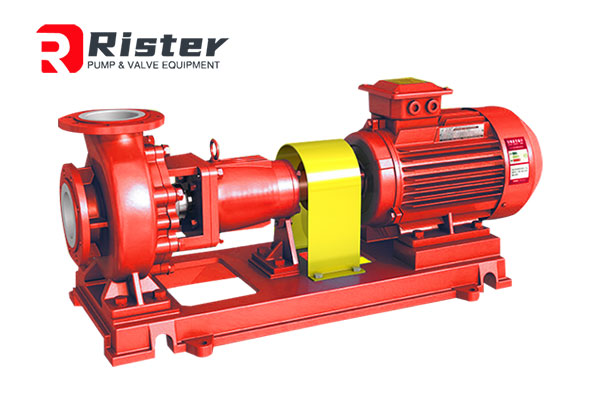

-IHF fluoroplastic centrifugal pump is a new generation of corrosion-resistant centrifugal pump based on IH pump. It combines the advantages of various chemical pumps and is suitable for long-term transportation of various acids, oxidants and other corrosive media of any concentration at the temperature of-20 ℃ ~ 120 ℃. The impeller and pump cover are surrounded by metal insert fluoroplastic, and the pump body is lined with fluoroplastic (F46). Enough to withstand the weight of the pipe and withstand mechanical impact, the shaft seal adopts advanced external bellows mechanical seal, the static ring adopts 99.9% alumina ceramic, and the moving ring adopts tetrafluorine filling material, which is characterized by good corrosion resistance and wear resistance. With the back-pull structure, one person can easily carry out internal routine maintenance and parts replacement, without the need to disassemble the pump inlet and outlet pipe.

In the selection of two types of pumps should be taken into account, the price of FSB pump is relatively lower than IHF pump, in the inlet and outlet pipeline requirements of less than DN80, flow head below 30m3/H can be selected. Relatively large requirements of the IHF pump is more suitable, the metal shell of the IHF pump can better withstand the gravity of the pipe. Maintenance and replacement parts are also relatively simple and relatively safe.