Which pump is more suitable for transportation of acid-containing wastewater?

Acid and lye is a common raw material in the chemical industry, in which there is more acid, but because of the particularity of acidity, the materials selected by many acid-resistant pumps can not be used in the transportation of acid. Common cast iron and stainless steel materials also need to be combined with working conditions to determine whether they are suitable or not. At present, the materials mainly used for transporting liquids are plastics and fluoroplastics.

1. Pump for transporting acetic acid.

It is one of the most corrosive substances in organic acids. Steel is usually seriously corroded in acetic acid at all concentrations and temperatures. Stainless steel is a good anti-acetic acid material, and molybdenum-containing 316 stainless steel is also suitable for high temperature and dilute acetic acid steam. High alloy stainless steel and fluoroplastic magnetic pumps can be selected when strict requirements such as high temperature and high concentration acetic acid and other corrosion media are required. Such as CQB magnetic pump, CQ316L stainless steel magnetic pump.

2.Pump for transporting sulfuric acid.

Sulfuric acid pump can be divided into dilute sulfuric acid pump and concentrated sulfuric acid pump, the former can choose a wide range of selection, dilute sulfuric acid pump can choose engineering plastic pump, ceramic pump, F46 pump, F26 pump, the latter (concentrated sulfuric acid pump) can only choose fluoroplastic (F46) pump. Concentrated sulfuric acid usually corrodes engineering plastics, but fluoroplastics do not. In addition, it is necessary to pay attention to the high density of concentrated sulfuric acid and the high power of the motor when selecting the pump. The simple algorithm is that the shaft power * 1.84 is the shaft power when transporting concentrated sulfuric acid.

3. Pump for transporting hydrofluoric acid.

Hydrofluoric acid is very corrosive, fluoroplastic magnetic pump is recommended (and be sure to replace the ceramic parts of this series of pumps with hydrofluoric acid-resistant materials).

4. Pump for transporting nitric acid.

Fluoroplastic magnetic pump is recommended for nitric acid pump, and the rubber sealing ring should be replaced with tetrafluoro material.

5. Pump for transporting salt water (sea water).

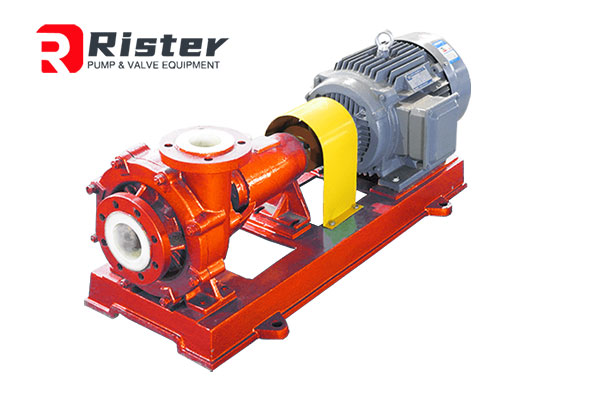

Usually, the corrosion rate of iron and steel in sodium chloride solution and sea water and salt water is not too high, so it is usually necessary to choose paint protection; all kinds of stainless steel also have a very low uniform corrosion rate, but it may cause local corrosion due to chloride ion. 316 stainless steel is usually better, but its cost is higher. Fluoroplastic centrifugal pumps, such as IHF corrosion-resistant chemical pumps, are recommended.

6. Pump for transporting hydrochloric acid.

The common concentration of hydrochloric acid is 38%, therefore, the hydrochloric acid pump is basically as long as the material selected by the overcurrent parts is plastic, but from the service life, performance-to-price ratio and other aspects, you can choose FSB fluorine alloy centrifugal pump or CQB-F magnetic pump, the price and performance of these two pumps are satisfactory.

Note: the sealed magnetic pump is in the form of static seal, so there is no need to consider the sealing. The centrifugal pump usually adopts external bellows mechanical seal, which has good corrosion resistance and wear resistance, such as the transport medium contains particles. Hard-to-hard mechanical seal can be selected.

Key points of selection of acid-proof pump:

1. First understand the acid-base characteristics of the medium. General medium PH value between 5: 9, choose FRPP (polypropylene plus glass fiber) selected material on the line, if the PH value is less than 5, it is a strong acid, it is appropriate to choose PVDF (polyvinylidene fluoride), if the PH value is greater than 9, it is a strong alkali, it is appropriate to choose the material selected by pure PP or CPVC.

2. define the medium flow rate and the distance height between the transportation to determine the power of the acid-proof pump, and the flow rate of the acid-proof pump is inversely proportional to the lift.

3. It is necessary to make clear whether there are granular impurities with high hardness in the medium. To correspondingly adopt the shaft seal material of acid-proof pump.

4. It is necessary to make clear the installation environment of the acid-proof pump so as to confirm whether the acid-proof pump should have the function of self-priming.

5. To make clear the temperature, it is easy to confirm the material of the acid-resistant pump body and whether the high-temperature bearing is used.