Installation and operation preparation of single-stage centrifugal pump

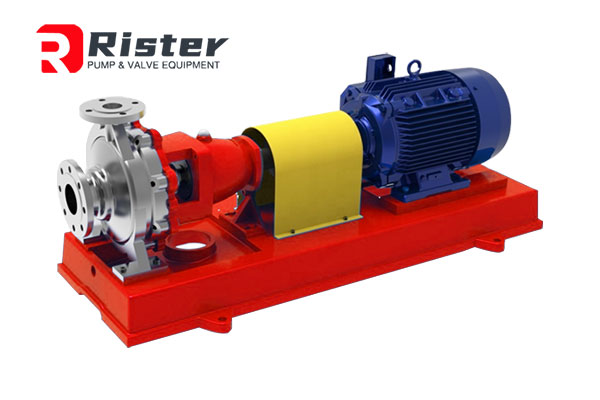

1. When installing a single-stage centrifugal pump, the parts of the equipment should be clearly defined. Generally speaking, the single-stage centrifugal pump is mainly composed of pump shell, impeller, sealing ring, shaft, bearing, shaft seal and so on. In the initial installation, the general construction is to install the pump first, and then install the inlet and outlet pipes on the basis of the short section of the pump inlet and outlet.

2. If the rationality of pipe support is not considered during installation, if the outlet pipe is supported by wall or cantilever column support when passing through the wall, although part of the space is saved, however, due to vibration, temperature change, material gravity and other reasons, wall support and pipe cantilever support deformation and sinking, serious will also cause impeller shaft fracture, bearing damage.

3. Some centrifugal pump experts have also made a reminder that when installing a single-stage centrifugal pump, it is necessary to match the appropriate pipeline according to the head of the centrifugal pump and pay attention to the water level of the outlet pool. In addition, do not use too many elbows on the intake pipe, and pay attention to the angle of the axis and degree surface of the water pipe.

4. Take the water level of the outlet pool as an example, if the outlet is higher than the normal water level above the outlet pool, on the surface, the head will increase, but this will result in a significant reduction in discharge. In practical work, due to the influence of topographical factors, if the position of the outlet pipe must be higher than the normal water level of the pool, an elbow or some short pipes can be added to the diameter of the pipe.

5. Be prepared before you run, and the next step at the end of the installation process is to run. It should be reminded that the operator had better not rush to run the equipment, which needs to be fully prepared before. First of all, the operator needs to check the valves on the pump outlet and inlet lines, flanged anchor bolts, couplings, thermometers and pressure gauges. Only when these parts are checked, can the safety and stability of the equipment be ensured.

6. Check the operation of the single-stage centrifugal pump, turn the car first, listen to the noise and see if it is flexible. Then open the inlet valve, discharge the gas from the pump body, fill the pump with the liquid to be transported, and then close the outlet valve. Next, the operator needs to add lubricating oil or grease to the pump tank.